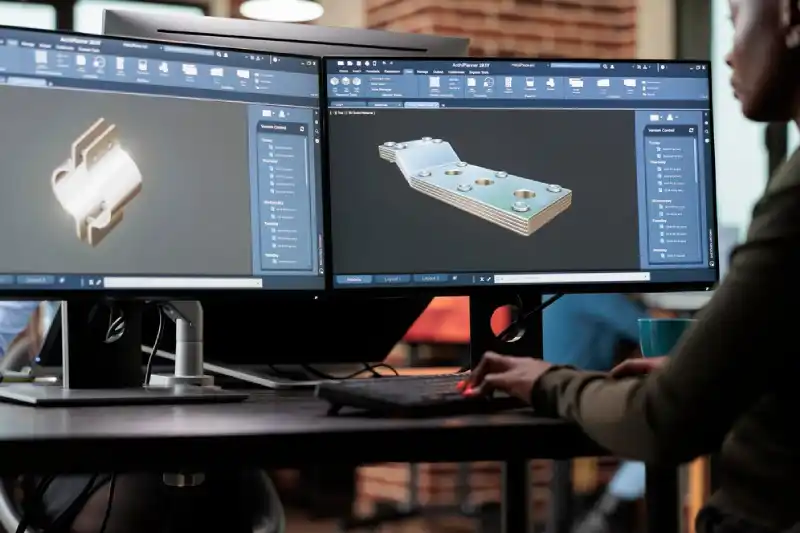

In today’s world, CAD (computer-aided Design) and CAM (computer-aided Manufacturing) have become essential tools for almost every company.

These technologies have dramatically transformed industries worldwide, leading to rapid growth across many sectors. There are also CAD CAM software for beginners, which makes it more accessible for novice designers.

Let us discover the benefits of using the best CAD CAM software for CNC and other businesses.

What Is CAD?

Computer-aided Design, or CAD, is software for creating digital representations of physical objects. It can encompass both two-dimensional (2D) drawings and three-dimensional (3D) models.

CAD software has revolutionised the design process across various industries, from engineering and product development to architecture and construction.

Imagine a world where intricate car parts or the layout of a new building were first meticulously drawn by hand. CAD offers a significant leap forward, allowing designers to create these elements digitally.

This software provides a vast toolbox for building these digital models. Lines, shapes, and curves can be precisely defined, and features like extruding and revolving allow the creation of complex 3D objects.

You can view the models from CAD CAM software for 3D printing from any angle, manipulate them virtually, and even analyse them for properties like strength or weight.

What Are the Benefits of CAD?

CAD software offers many benefits that have transformed how Design is done across various industries. Here are some of the key advantages:

Improved Productivity

Traditional design workflows involved meticulous hand-drafting, a time-consuming and laborious process.

Each element of a design, from lines and curves to intricate details, had to be drawn individually. It meant that making changes often required starting from scratch, further adding to the time investment.

CAD software made the process easier by introducing a digital environment through CAD software for complex CNC machining and designing. Features like copy-paste allow designers to replicate elements quickly, saving significant time compared to redrawing them by hand.

Modifying existing designs is now easier with CAD CAM software for complex designs. With a few clicks, dimensions can be adjusted, shapes tweaked, and details added or removed. Digital libraries offer a treasure trove of pre-made components, further accelerating the design process.

Imagine a designer needing to include a standard bolt in their drawing. With CAD, they can simply select it from a library and insert it into their Design, eliminating the need to draw the bolt themselves.

These functionalities combined translate to a dramatic increase in design speed, allowing designers to focus on creativity and innovation rather than tedious drafting tasks.

Enhanced Accuracy

While a valuable skill, manual drafting is inherently prone to human error. A design’s accuracy relies heavily on the precision of the drafter’s hand and eye.

Even minor inconsistencies, such as misplaced lines, inaccurate dimensions, or unintended gaps between components, can creep in.

These errors might not be immediately noticeable but can lead to significant problems, causing delays and additional costs during manufacturing or construction.

CAD software introduces precision and control that manual drafting simply cannot match, making it an excellent CNC design software for beginners. Dimensions can be entered digitally, ensuring absolute accuracy.

CAD software for wood projects can also enforce geometric constraints, preventing lines from being accidentally drawn at the wrong angle or shapes having incorrect proportions. Many CAD programs offer automatic error-checking functionalities.

These features can identify inconsistencies like overlapping elements, missing dimensions, or violations of design rules, alerting the designer to potential problems before they become costly mistakes.

Better Design Quality

Manual drafting methods have limitations when it comes to complexity. Imagine an architect trying to visualise a sprawling building with intricate curves and interlocking components solely through hand-drawn plans.

The process would be cumbersome and prone to errors. CAD software breaks these limitations, offering a powerful toolbox for creating highly complex designs.

Advanced features like 3D modelling allow designers to build digital prototypes that can be viewed and manipulated from any angle. It creates a deeper understanding of the Design’s spatial relationships and functionality.

CAD software also facilitates the creation of intricate curves and organic shapes that would be difficult, if not impossible, to achieve with traditional drafting tools. It opens doors for innovative and aesthetically pleasing designs.

Increased Accessibility

Modern CAD software for 3D printing and design prioritises user-friendly interfaces. Among the features with user interface customisation in CAD software are the customisable toolbars, keyboard shortcuts, and visual aids. They make navigating the software more accessible for users with varying levels of experience and physical abilities.

Many programs also offer accessibility options, such as screen reader compatibility and adjustable text size, to cater to users with visual impairments.

It also promotes collaboration by allowing multiple users to work on the same Design simultaneously. It can be particularly beneficial for individuals with mobility limitations who might struggle with traditional paper-based workflows.

CAD software also offers a high degree of design flexibility. Parametric modelling allows users to define design relationships and rules.

Changes made to one element can automatically propagate to other connected components, saving time and effort for users with dexterity limitations.

More Streamlined Workflow

CAD integrates seamlessly with other design and manufacturing programs, particularly CAM software with simulation features.

It creates a smooth workflow from the initial design concept all the way to production. Imagine a designer finalising a complex gear in CAD.

Traditionally, they would need to translate those 2D drawings or 3D models into instructions for manufacturing software. With integrated CAD/CAM systems, you can transfer the information directly.

It eliminates the risk of errors from manual data entry and streamlines the entire process, saving time and ensuring a more accurate transition from Design to physical product.

Reduced Expenses

While the initial investment in CAD software might seem like a cost, it is an investment that pays off in the long run.

The errors of manual drafting can snowball into costly consequences during production, requiring rework or scrapping of materials.

CAD software mitigates these issues through features like automatic dimensioning, error checking, and precise 3D modelling. Affordable CAD CAM software suite reduces the need for costly rework and wasted materials, leading to significant cost savings.

It also allows designers to create highly detailed and accurate digital models. It leads to precise material calculations, reducing waste during production.

Also, features like nesting or optimising material layout for cutting can further minimise material consumption, especially for sheet metal or fabric projects.

The best CAD CAM software for CNC also helps companies operate more cost-effectively throughout the Design and manufacturing process.

Improve Your Designs with CAD CAM Software

CAD CAM software is your key to unlocking a world of design possibilities. Imagine crafting intricate objects, streamlining your workflow, and bringing your vision to life with incredible precision with Alphacam NZ.

Let’s take your creativity to the next level, utilise Alphacam CAD CAM software now. For more information, please contact us by calling +64 9 947 4288.